What is the mean time between failures (MTBF) of data acquisition systems?

The search for a suitable data acquisition device can be long and complex. Many different aspects must be considered. During the decision-making process, the information in the data sheets is closely checked and compared with each other. The MTBF value can play a significant role here. It indicates the average operating time of a system between failures or downtimes. In this blog post, we will take a closer look at this value and give you helpful tips for practical use.

What is MTBF?

MTBF or Mean Time Between Failures describes the predicted elapsed time between failures of a mechanical or electronic system during standard operation. The MTBF is standardized in IEC 60050 and describes it as “The expected value of the operating time between two consecutive failures.”

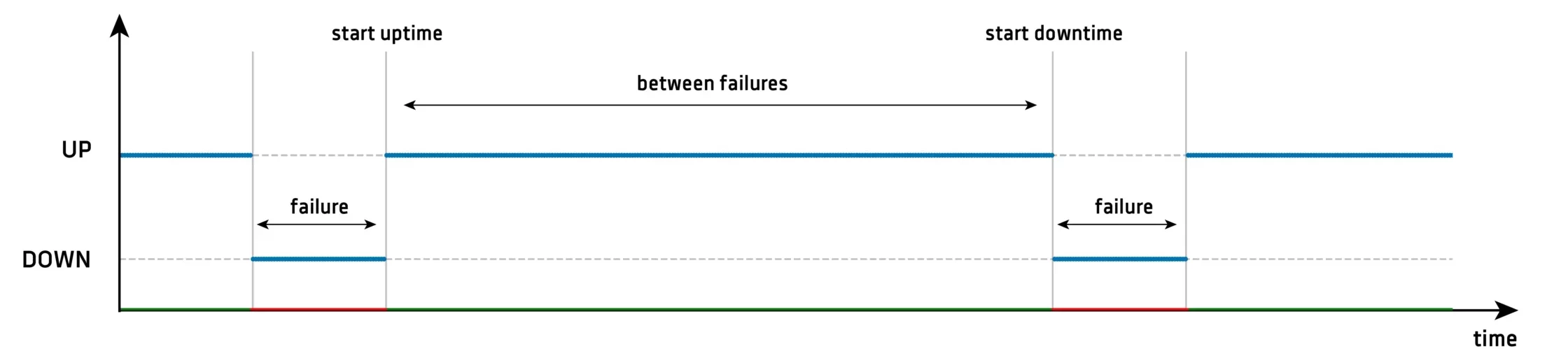

Figure 1: Graphical representation of the operating status of a system over time.

From the mathematical point of view, the MTBF can be described with the following equation:

![]()

Equation (1)

It is important to note that MTBF describes the mean time between repairable failures. The average elapsed time for non-repairable failures is described with another term: the so-called MTTF – Mean Time to Failure. In this article, however, we will focus on MTBF, with an emphasis on data acquisition systems.

MTBF for data acquisition systems

When considering the MTBF of data acquisition systems, it is important to distinguish between the MTBF for the data acquisition components and the MTBF for the chassis. For PC-based all-in-one data acquisition chassis, the most critical components for the MTBF calculation are always the display and the power supply. Both components typically have an MTBF of 100 000 hours. The following equation determines the combined MTBF of several components, all of which are important for the correct functioning of the system, with n representing the number of components:

![]() Equation (2)

Equation (2)

Calculating the combined MTBF of a display and a power supply with 100 000 hours each MTBF will result in 50 000 hours combined MTBF.

But why do displays and power supplies have an MTBF of 100 000 hours?

The reason for the display is the LED backlight, which deteriorates over time. After 3.5 years of continuous operation without a screen saver, the display only has half the luminosity. With an active screen saver, it would last longer. The reason for the power supply is the wear of the integrated fan. The power supply unit itself, however, can be replaced very easily.

Practical example: “Calculating the MTBF of a DAQ chassis”:

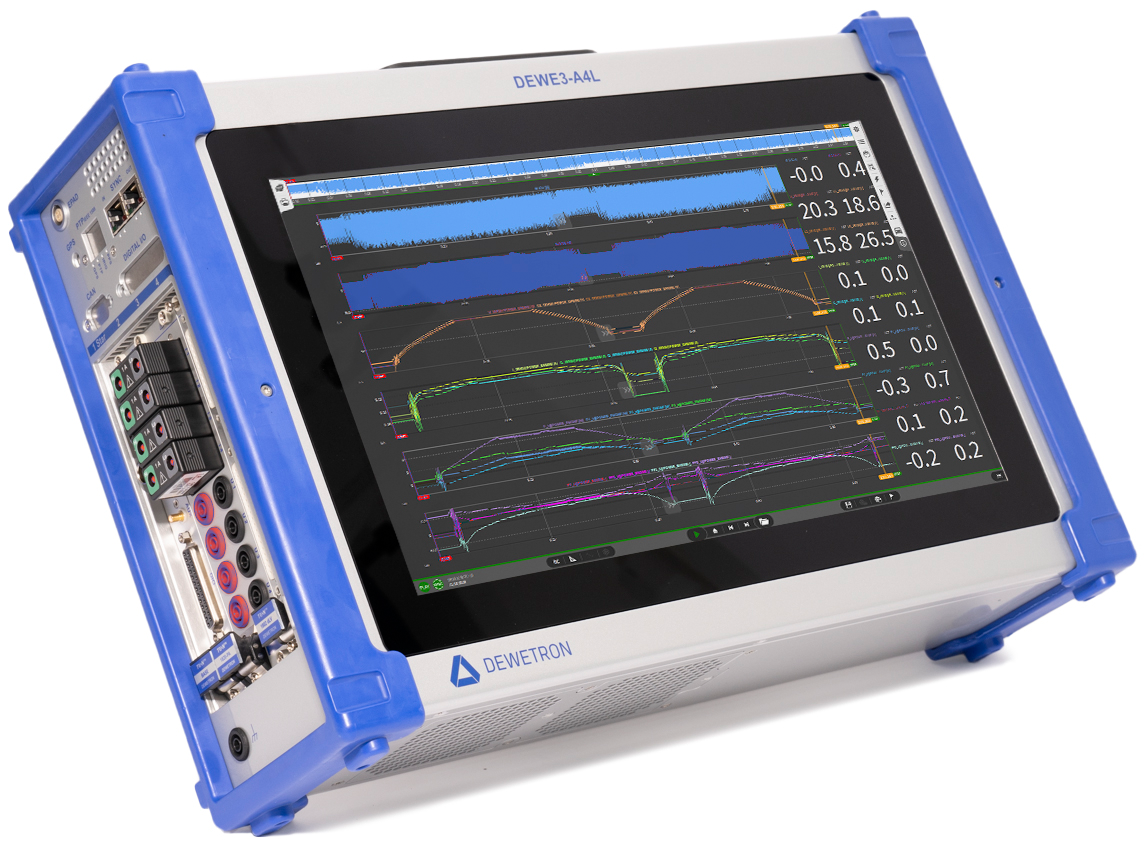

For this case study, we calculate the MTBF of a DEWETRON data acquisition system. The DEWE3-A4L is an all-in-one data acquisition system for continuous high-speed recording applications. It can be equipped with 32 analog measurement inputs and has a built-in 15.6” multi-touch display.

Using equation (2) to calculate the combined MTBF of all components included in a DEWETRON DEWE3-A4L chassis will result in 28 968 hours (~3.3 years) MTBFcombined . This means that a DEWE3-A4L chassis is expected to run ~3.3 years permanently without failure. But normally a data acquisition system like the DEWE3-A4L is not used in 24/7 operating mode. Assuming the system is used ~8 hours per working day the system can be used ~10 years without a failure occurring. After this time, it is likely that either the power supply or the display needs to be changed. This is an acceptable maintenance task after 10 years and does not afford a huge investment.

Figure 1: DEWE3-A4L

Practical example: “Calculating the MTBF of a DAQ module”:

In addition, the MTBF of the data acquisition module is specified separately. For this example, we have calculated the MTBF of a DEWETRON data acquisition module. The TRION3-1820-MULTI-4-D module can be put into a DEWETRON DAQ system like the DEWE3-A4L and allows the user to measure data over 4 channels at 2 MS/s.

The TRION3-1820-MULTI-4-D board has 196,187 hours (~15.8 years) MTBF. Again assuming 8 hours of use per day will result in ~47 years.

Figure 2: TRION-1820-MULTI-4-D

Please note that calibration is not considered here. The system needs to be calibrated at regular intervals to ensure accuracy. DEWETRON guarantees the specified input accuracy for 1 year @ 23° C ± 5 °C.

In a nutshell

MTBF is a statistical quantity that describes the time between recoverable failures. It does not describe the minimum lifetime of a system. In the design phase, MTBF is used as an indicator to evaluate the failure rate of a combined complex system and to select other components if necessary. In the operational phase, MTBF can help assess whether a faulty system should be repaired or replaced. It also supports you in scheduling maintenance work or procuring spare parts.