How to measure vibrations?

Measuring and monitoring vibrations is a key part of machine maintenance. It allows you to track your machine’s health, provides insight into its conditions and may reveal arising equipment failures. However, measuring vibrations is not as simple as it seems. Due to the many components of a vibration, the measurement process is quite complex. Additionally, depending on the type of vibration sensor, the measurement process also varies.

What are vibrations and how to quantify them?

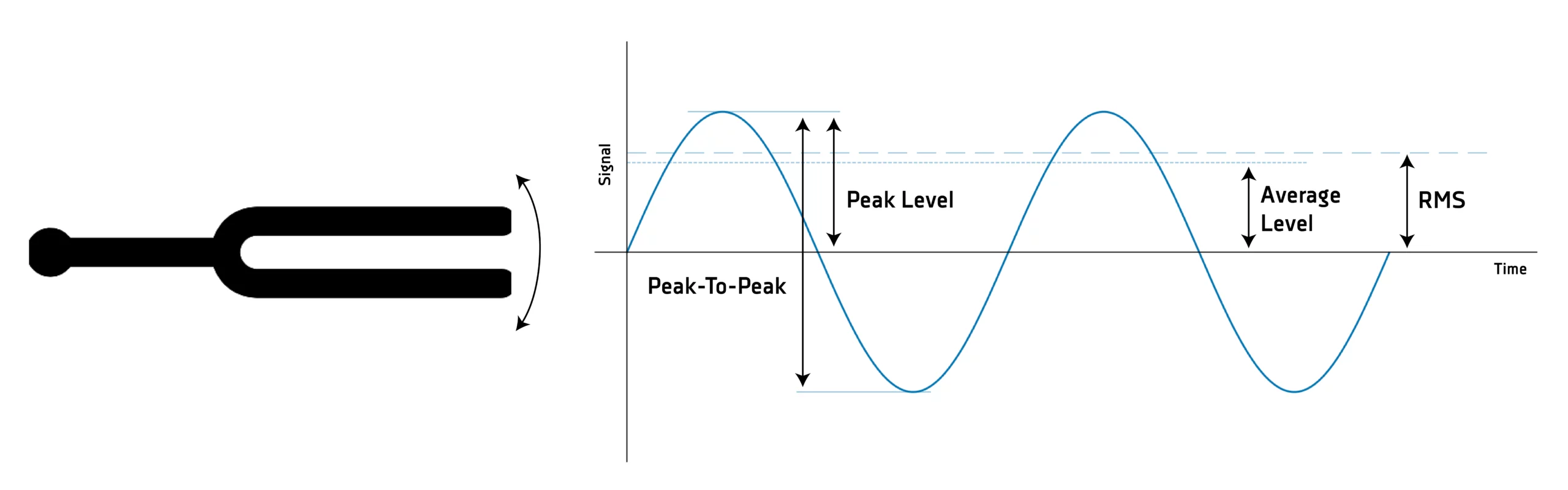

To put it briefly, vibrations are periodic mechanical oscillations of bodies around an equilibrium point. These oscillations (and therefore vibrations themselves) are quantified by their acceleration, velocity, displacement, and frequency. To determine these components, we analyze the oscillation frequency and amplitude typically in terms of peak-to-peak, peak level, average level, or RMS measurements.

Figure 1: Analysis methods of an oscillation signal of a vibrating tuning fork.

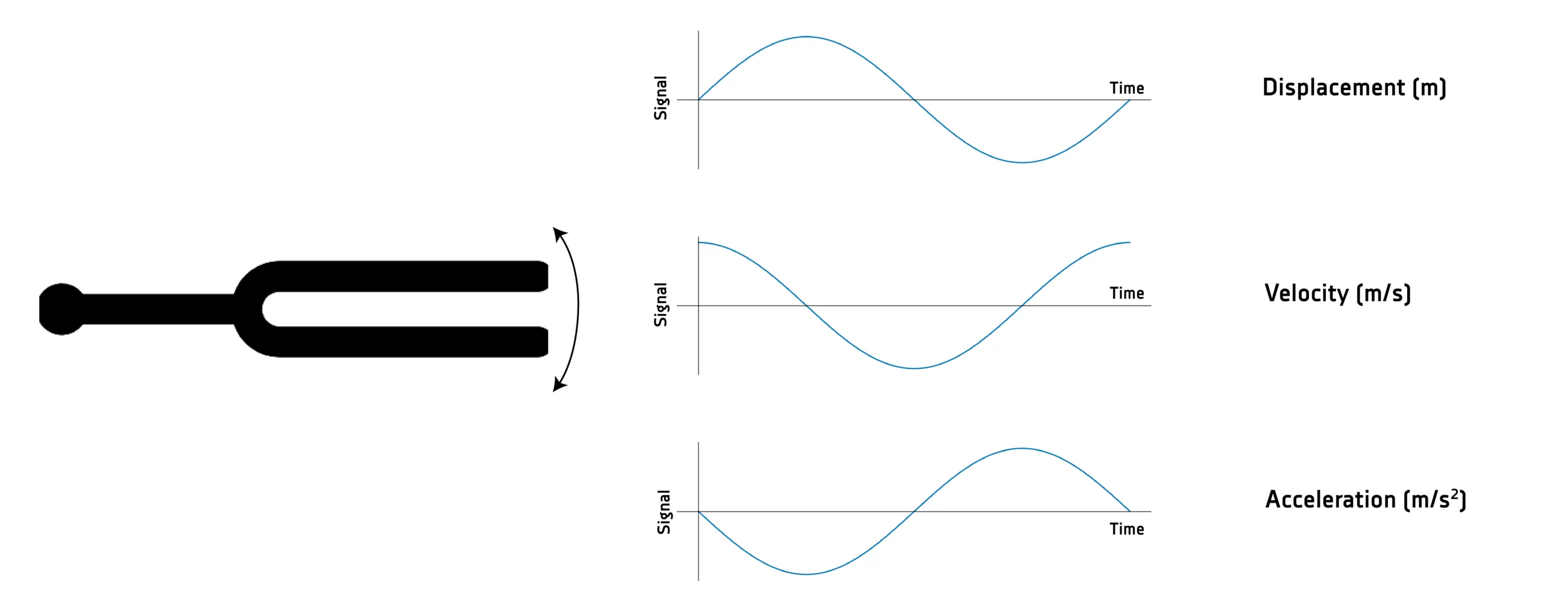

For example, let us consider a tuning fork. By striking the fork, it will start to vibrate or else oscillate. The amplitude of the resulting wave then corresponds to the physical displacement of the ends of the fork compared to their resting positions. Additionally, it is also possible to describe the displacement of the fork in terms of acceleration and velocity due to the relation between these components by a function of time (or frequency).

Figure 2: Vibration signals of a tuning fork as a function of time, shown as local displacement, velocity, and acceleration.

What types of vibration sensors are there?

Vibration sensors come in various forms depending on their usage and industrial application: strain gauges, microphone sensors, laser displacement sensors, Eddy-Current sensors, and many more.

Accelerometer

However, the by far most common type of vibration sensor is the piezoelectric accelerometer. As its name implies, these sensors measure the vibratory acceleration of an object by use of the piezoelectric effect.

Excursus: piezoelectric effect

The piezoelectric effect describes the ability of a material to generate a measurable electric field due to applied mechanical stress. This means if a piezoelectric material experiences any form of mechanical force, it generates an electrical charge which is proportional to the applied force.

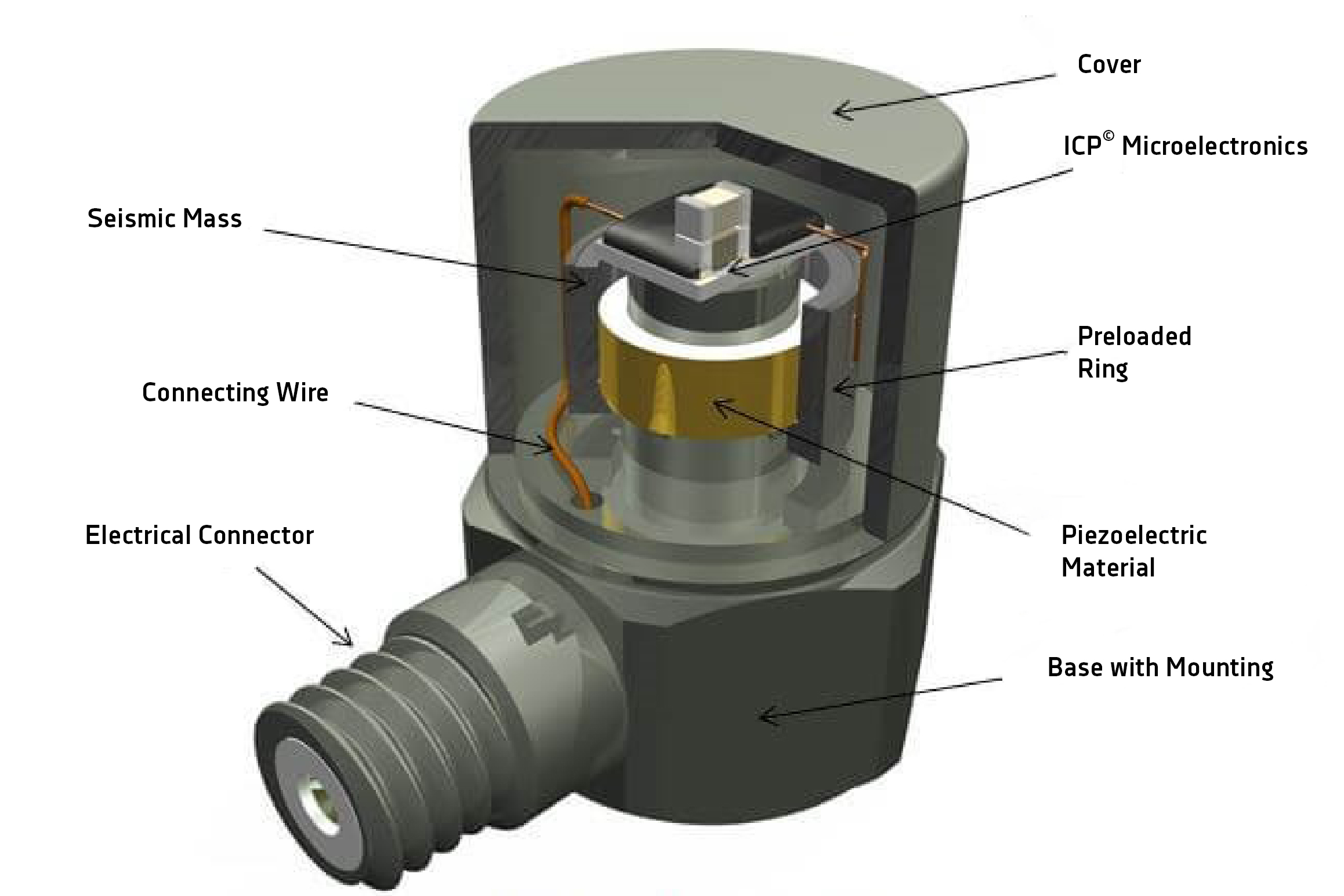

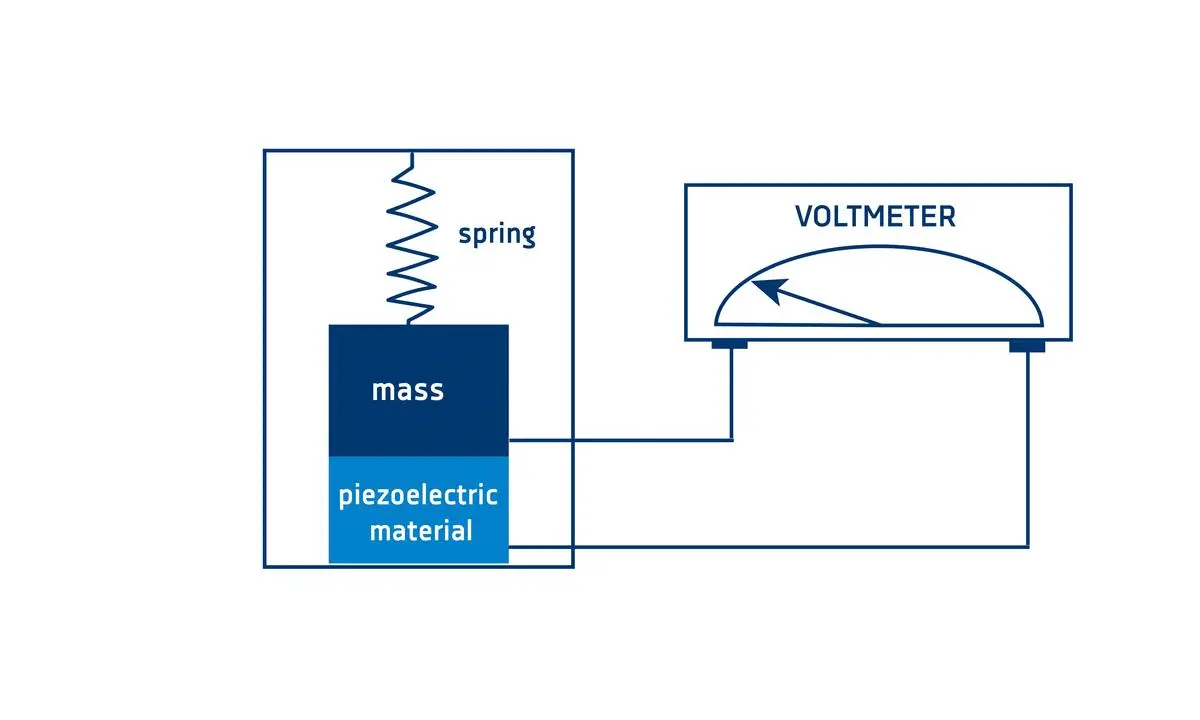

Design and working principle

An accelerometer is composed of a seismic mass, a spring, a piezoelectric material, some integrated microelectronics, and a base for mounting the sensor. Figure 3 displays a typical ICP accelerometer and figure 4 a simplified design and working principle. What happens is that due to every single vibration, the sensor accelerates. The seismic mass, therefore, is displaced and applies a force onto the piezoelectric material according to Newton’s 2nd law of motion (force = mass x acceleration). This results in a change of electrostatic force or voltage of the material which can be measured. In general, the measurable signal is already amplified before it is read out with an integrated IC amplifier. However, the measurement itself still requires an external device like a voltmeter or a DAQ (data acquisition) device.

Figure 3: Typical design of an ICP accelerometer.

|

Figure 4: Simplified design and working principle of an accelerometer. Figure 4: Simplified design and working principle of an accelerometer. |

How does vibration measurement work at DEWETRON?

DEWETRON is a specialist in the field of measurement technology and offers a big range of measuring instruments. Especially our 1620-ACC-, 2402-dACC-, and MULTI measuring boards are optimized for vibration measurements and specially designed for acceleration sensors. These measurement boards already have a built-in power supply required by the integrated electronics of the sensor, which a simple voltage input does not have.

Depending on the series our boards can be incorporated into either a DEWE2 or DEWE3 DAQ system. Including our classical mainframe systems for test benches, our TRIONET front-end expansion plus our portable all-in-one DAQ systems. In combination with our MSI-BR-ACC adapter, it is further possible to operate accelerometers with PUREC – our portable, expandable, and easy-to-use data recorder.

Interested in our products? – Check them here!

| DAQ Systems | Measuring Boards | PUREC |

Long story short

Vibration monitoring is essential for any business with heavy equipment and machines. The measuring process itself is quite complex and heavily depends on the type of applied sensor, with the accelerometer being the most commonly used. In addition to most of the sensors, a DAQ system is required for data readout and representation. For this purpose, DEWETRON presents a variety of options, including customized measurement boards and various DAQ systems.