Crash Tests with Split-Hopkinson Pressure Bar

What is the customer’s measurement task?

Our client operates a well-respected research and development facility in a university setting with a mission to simulate automotive accidents in order to model comprehensive and meaningful crash tests. The customer is now placing increased focus on electrified vehicles. Although some of the parameters have changed as a result, material tests are still high on the agenda for our customer. For this purpose, the customer also resorts to the split-Hopkinson compression bar method, for example (you can learn more about the Split-Hopkinson compression bar method here).

Which configuration provided the right system?

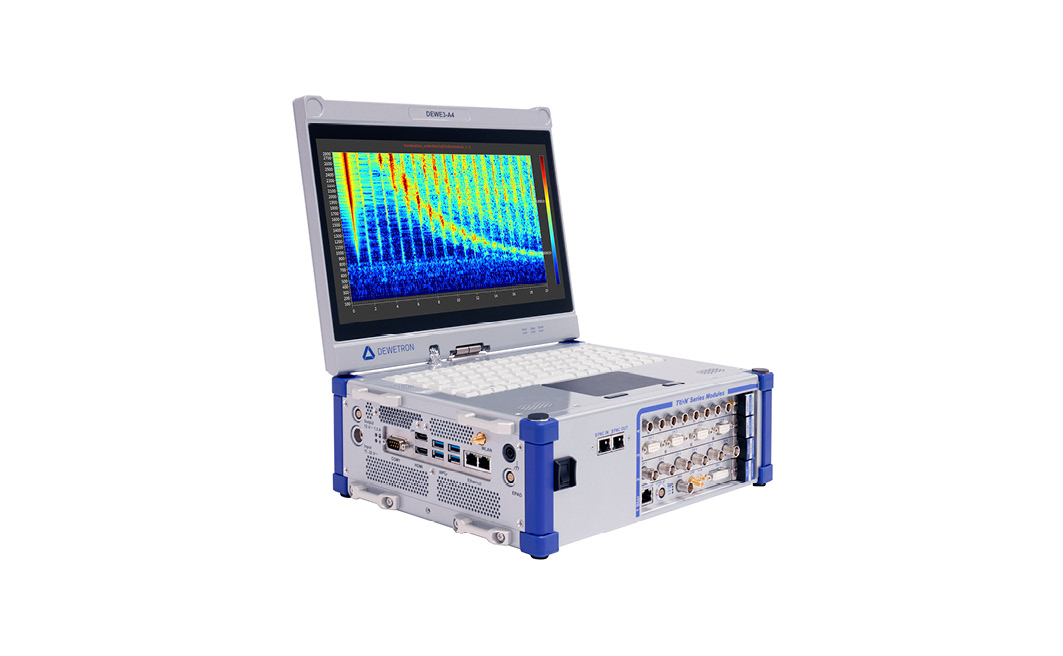

Our customer chose our DEWE3-A4 measurement system because it is an all-in-one system with a built-in PC, integrated data storage, four slots for exchangeable TRION/TRION3 modules, and a 13″ multi-touch widescreen full HD display, offering everything needed for both mobile and stationary use. The system was equipped with two of our TRION3-1850-MULTI modules, as the all-rounder can be used to measure a wide range of signals with a very high sampling rate and bandwidth. In addition, the customer uses the TRION-BASE module for perfect synchronization of the measurement.

Which signals/physical units does the customer want to measure?

DEWETRON’s TRION3-1850-MULTI-4D module offers the customer the flexibility to measure a variety of signals using a wide range of sensors. For the current application, the customer is recording material data such as deflection, compression, strain, and torsion. Bridges and strain gauges are used for this purpose.

Why was OXYGEN the right choice? Does the customer use additional software options?

The fact that you can use OXYGEN to create extensive analyses and reports even during the measurements was an important aspect for the customer. The fact that you can structure these analyses and reports very individually thanks to the numerous visualization methods in OXYGEN was a great bonus for the customer. This way, the customer prepares the data for various stakeholders in one and the same program – using drag and drop thanks to touchscreen operation. If you want to learn more about the tools in OXYGEN, we recommend Part I and Part II of our OXYGEN overview articles.

In addition, OXYGEN also scored points with its wide range of functions: The PreTime settings for executing triggered measurements proved to be perfect for the application. In addition, the video from the highspeed camera can be seamlessly embedded in the measurement file and played back synchronously with the measurement at a wide range of speeds. Moreover, our customer uses the function to save measurement files such as videos. Lastly, the uncomplicated export for Matlab also contributed to the customer’s purchase decision.

How does further data processing look like?

The customer evaluates some of the measured variables immediately in OXYGEN with the help of online analyses. This enables the display of essential information immediately during the measurement which allows reacting accordingly. In addition, the customer has developed an evaluation method in Matlab for the application. Therefore, after the initial evaluation in OXYGEN, the data is exported in the correct data format to trigger specific analyses.

Where does the customer want to use the system?

Our customer uses the measurement system directly at the test bench of the research institute. Currently, the DEWE3-A4 is not integrated into any existing infrastructure. However, since the customer would like to change this in the future, the measurement system with its multitude of synchronization methods offers the necessary flexibility to implement future applications.

How does the customer want to access the system?

The customer works directly on the system. The 13″ multi-touch widescreen full HD display regularly proves useful here. Integration into existing infrastructure is planned for the future but is not yet being used.

Which sampling rate does the customer need?

The customer works with a very high sampling rate of more than 5 MS/s per channel.

What about the bandwidth?

High bandwidth is essential for the customer’s application – in this specific case, it is greater than 1 MHz.

Does the application require sensor power supply?

Yes, the strain gages require a bridge supply. The sensor supply is ensured via the TRION3-1850-MULTI-4D module, which is freely programmable in the range from 0 V to 24 V.

How long does the measurement take? Is a triggered measurement necessary?

In this application, the measurement only takes a few milliseconds, hence it is essential to set a trigger. The trigger is released with 100 ms PreTime when the launch signal is pressed.

Why did the customer choose DEWETRON equipment over other products?

We are very proud that our measurement hardware was convincing at all levels in this project. This means that the customer was not only impressed by the high sampling rate of 5 MS/s and the high bandwidth of more than 1 MHz, but also by the entire range of functions of the measurement system. In contrast to comparable products from other suppliers, DEWETRON’s system can record longer periods of time and save measurements – thanks to the built-in and replaceable 256 GB SSD, this is easy and uncomplicated even for data-intensive applications. In addition, the fast possibility of data evaluation directly on the system and during the measurement with the help of online analyses and a built-in touch display was another plus point.

Meet our expert to talk about this application

Ivica Baresic – Business Development & Sales Austria at DEWETRON – guided the customer through the entire project with advice and assistance. “If you cannot measure it, you cannot improve it” is his professional credo and so he finds the right measurement solution for all challenges. He supports many customers from industry and research institutions to initiate optimization processes from prototypes to processes and to deliver high quality products. Click here to cennect with him on LinkedIn..

EMAIL: [email protected]

PHONE: +43 316 3070280