Mechanical Motor Analysis

What is mechanical motor analysis?

Apart from electrical parameters, mechanical variables play a major role in practice. When thinking of an electric motor, for example, quantities such as current and voltage first come to mind. However, other characteristics are also important for the operation of electric motors: How fast does the motor work? What noise does it generate? Do vibrations occur? These are all mechanical variables that one tries to observe by means of mechanical motor analysis.

Mechanical motor analysis obviously finds application in the automotive industry. However, mechanical properties of engines are also important in other industries, for example when operating an emergency power generator. In many cases, mechanical characteristics are even more important than electrical ones, such as when flying a propeller-driven airplane.

What variables play a role?

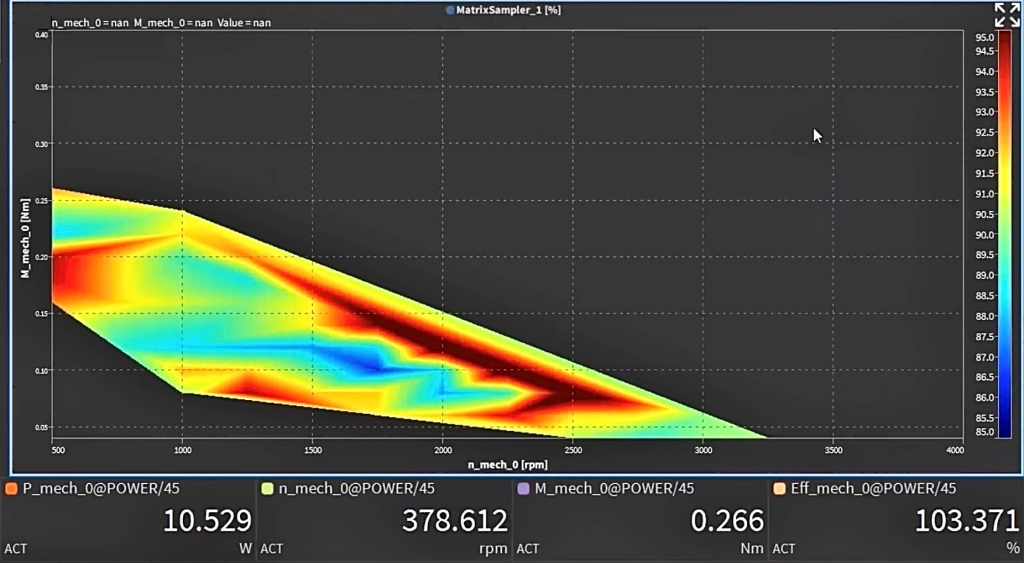

What do you look for when buying a car? For many, the horsepower or even speed of the car is a crucial factor. To determine these quantities, the torque and rotational speed are identified in the mechanical motor analysis. Depending on these two properties, one can calculate the power and efficiency of an engine.

In mechanical motor analysis, it is also very important to determine the optimum operating point. An engine can often have power losses at very high or low speeds. In everyday use of a car, however, these losses should be as low as possible, because otherwise the gas station bill may be high. Mechanical motor analysis can now be used in the development of engines to minimize power loss in typical ranges.

Another important part of mechanical motor analysis is the occurrence of vibrations and noise. As already explained in the blog post on NVH, minimizing these variables improves the driving experience, and can therefore reduce the number of returns on already sold models. But vibration also creates some hazard potential. If the vibration of an engine is too strong, this leads to premature aging of components. If a vibration also encounters a resonant frequency, the vibration can be amplified to such an extent that components may even break down while the vehicle is in motion. Engineers have therefore to ensure that this never happens.

DEWETRON’s solution for mechanical motor analysis

DEWETRON is a manufacturer of high-precision and modular measuring and testing equipment. Apart from this, we develop the OXYGEN software, which is ideally suited for mechanical motor analysis.

OXYGEN offers a wide range of features. For example, you can directly combine speed and torque to form a performance indicator. OXYGEN also makes it easy for you to evaluate sound pressure level and vibration. You can choose between logarithmic and linear scales, take the frequency-weighted sound pressure level into account and even display the data in a matrix map.

The matrix map is also the perfect tool for creating a power characteristics map of a motor. This is necessary to find the optimum operating point of an engine. The following figure shows how such a performance map may look like.

Matrix map for analyzing efficiency (color relates to efficiency)

OXYGEN also supports a variety of basic analysis tools. For example, you can create FFT or CPB spectra. To bring you even closer to this topic, we have already produced a whole video tutorial on mechanical motor analysis, which you can find here.

If we have caught your interest, you can find all information about OXYGEN and our measurement modules on our DEWETRON website. Video tutorials, whitepapers and much more can be found there as well. To stay up to date, you can also follow us on Twitter or LinkedIn.