TRION3 & TRION modules with A/D converter

Our multi-channel signal conditioning modules provide separate A/D conversion on each channel and up to 24-bit resolution with anti-aliasing filters. Perfect simultaneous sampling for all analog input modules. You are absolutely flexible with the user-exchangeable TRION3 & TRION modules – just insert them in your suitable DEWETRON DAQ system.

There are two module series: The highspeed TRION3 modules are only compatible with the DEWE3 chassis. But TRION modules can be used in both, DEWE3 and DEWE2 chassis.

Choose between a wide range of modules:

| ANALOG MODULES POWER MODULES SUB-MODULES |

DIGITAL MODULES ANALOG OUTPUT MODULES |

ANALOG MODULES

| ANALOG MODULES | PDF |

CHANNELS | SAMPLE RATE/CH. |

RESOLUTION | ISOLATION | CONNECTOR TYPES |

|

|---|---|---|---|---|---|---|---|

| TRION3 -1850-MULTI

|

4 or 8 | 5 MS/s | 24-bit >2 MS/s: 18-bit |

ISO | 4 D-SUB or 8 LEMO 0B |

||

| TRION3 -1820-MULTI

|

4 or 8 | 2 MS/s | 24-bit >2 MS/s: 18-bit |

ISO | 4 D-SUB or 8 LEMO 0B |

||

| TRION-1820-MULTI

|

4 | 2 MS/s | 24-bit >2 MS/s: 18-bit |

ISO | 4 D-SUB | ||

| TRION-2402-MULTI

|

4 or 8 | 200 kS/s | 24-bit | ISO | 4 D-SUB or 8 LEMO 0B |

||

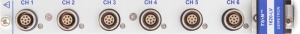

| TRION-1620-ACC

|

6 | 2 MS/s | 24-bit >1 MS/s: 16-bit |

ISO | 6 BNC or LEMO 1B | ||

| TRION-1620-LV

|

6 | 2 MS/s | 24-bit >1 MS/s: 16-bit |

ISO | 6 BNC or LEMO 1B | ||

| TRION-1810-HV

|

4 to 8 | 1 MS/s | 24-bit | ISO | Safety banana, CAT III 1000 V |

||

| TRION3 -1810-SUB-8

|

8 | 1 MS/s | 20-bit | ISO | Safety banana | ||

| TRION-1603-LV

|

6 | 250 kS/s | 16-bit | ISO | 6 BNC or LEMO 1B | ||

| TRION-2402-dSTG

|

6 or 8 | 200 kS/s | 24-bit | – | 8 LEMO 0B or 8 RJ45 |

||

| TRION-2402-dACC

|

6 or 8 | 200 kS/s | 24-bit | – | 6 BNC or 8 SMB |

||

| TRION3 -1802-dLV

|

16 or 32 | 200 kS/s 100 kS/s |

18-bit 24-bit |

– | D-SUB | ||

| TRION3 -1600-dLV

|

16 or 32 | 20 kS/s | 16-bit | – | D-SUB | ||

| Compatibility: The highspeed DEWE3 systems support both, TRION3 and TRION modules. The DEWE2 systems only support TRION modules. Here you find the overview of our DAQ systems |

|||||||

DIGITAL MODULES

| DIGITAL MODULES | CHANNELS | SAMPLE RATE/CH. |

RESOLUTION | ISOLATION | FEATURES | ||

|---|---|---|---|---|---|---|---|

| TRION-CNT

|

6 | 2 MS/s | 80 MHz | ISO | 6 channel advanced counter | ||

| TRION-DI-48

|

48 | 2 MS/s | 500 nsec | ISO | 48 highspeed digital IN | ||

| TRION-BASE

|

– | 2 MS/s | 80 MHz | – | Basic IO card with simple IRIG sync and 2 counter | ||

| TRION-VGPS-V3

|

– | 2 MS/s | 0.01 km/h <10 cm |

– | 100 Hz GNSS receiver for automotive applications | ||

| TRION-TIMING-V3

|

– | 2 MS/s | 12.5 nsec | – | Applies precision absolute time to measured data | ||

| TRION-CAN

|

4 | 1 MBit | – | ISO | D-SUB | ||

| TRION-ARINC

|

4 or 16 | – | – | – | Decoding of ARINC429 signals, export of decoded signals | ||

| TRION-MIL1553

|

1 or 4 | – | – | – | Decoding of MIL-STD-1553 signals, export of decoded signals | ||

| TRION-EtherCAT-1-SLAVE

|

100 | 500 S/s | – | – | Measurement data output | ||

| Compatibility: The highspeed DEWE3 systems support both, TRION3 and TRION modules. The DEWE2 systems only support TRION modules. Here you find the overview of our DAQ systems |

|||||||

POWER MODULES

| POWER MODULES | CHANNELS | SAMPLE RATE/CH. | RESOLUTION | ISOLATION | CONNECTOR TYPES |

||

|---|---|---|---|---|---|---|---|

| TRION3 -1810M-POWER

|

8 (4 U / 4 I) | 10 MS/s | 18-bit | ISO | Fixed: 4 x Safety banana, CAT III 1000 V – Exchangeable: 4 x Sub-Modules |

||

| TRION3 -1820-POWER

|

8 (4 U / 4 I) | 2 MS/s | 18-bit | ISO | Fixed: 4 x Safety banana, CAT III 1000 V – Exchangeable: 4 x Sub-Modules |

||

| TRION-1820-POWER

|

8 (4 U / 4 I) | 2 MS/s | 24-bit | ISO | Fixed: 4 x Safety banana, CAT III 1000 V – Exchangeable: 4 x Sub-Modules |

||

| TRION-1810-HV

|

8 (4 U / 4 I) | 1 MS/s | 24-bit | ISO | Fixed: 4 x Safety banana, CAT III 1000 V – Exchangeable: 4 x Sub-Modules |

||

| TRION3 -1810-SUB-8

|

8 | 1 MS/s | 18-bit | ISO | Fixed: 0 – Exchangeable: 8 x Sub-Modules |

||

| Compatibility: The highspeed DEWE3 systems support both, TRION3 and TRION modules. The DEWE2 systems only support TRION modules. Here you find the overview of our DAQ systems |

|||||||

ANALOG OUTPUT MODULES

| ANALOG OUTPUT MODULES | CHANNELS | SAMPLE RATE/CH. |

RESOLUTION | ISOLATION | CONNECTOR TYPES |

||

|---|---|---|---|---|---|---|---|

| TRION3 -1850-MULTI-AOUT-8

|

IN: 8 OUT: 8 |

IN: 5 MS/s OUT: 2.5 MS/s |

IN: 24-bit OUT: 32-bit |

IN: ISO OUT: ISO |

IN: LEMO 0B OUT: D-SUB, BNC |

||

| TRION3 -1820-MULTI-AOUT-8

|

IN: 8 OUT: 8 |

IN: 2 MS/s OUT: 2.5 MS/s |

IN: 24-bit OUT: 32-bit |

IN: ISO OUT: ISO |

IN: LEMO 0B OUT: D-SUB, BNC |

||

| TRION3 -AOUT-8

|

OUT: 8 | 2.5 MS/s | Up to 32-bit | ISO | OUT: D-SUB, BNC |

||

| Compatibility: The highspeed DEWE3 systems support both, TRION3 and TRION modules. The DEWE2 systems only support TRION modules. Here you find the overview of our DAQ systems |

|||||||

SUB-MODULES

Compatibility &

Sampling rates

There are two module series:

The highspeed TRION3 modules provide sampling rates up to 10 MS/s and are only compatible with the DEWE3 chassis.

But TRION modules can be used in both, DEWE3 and DEWE2 chassis with sampling rates up to 2 MS/s.

TRION3 & TRION modules record many disparate data sources in perfect synchronization: analog, digital, counter/encoders, GPS, CAN, timing, etc.

Signal conditioning with simultaneous sampling

Simultaneous sampling TRION3 & TRION signal conditioning modules are the heart and soul of the DEWETRON data acquisition systems.

TRION3 & TRION modules combine the power of simultaneous sampling and 24-bit ADC technology with advanced DEWETRON signal conditioning – plug one convenient module right into your DEWETRON system.

Plug’n’play TRION3 & TRION modules

Choose your TRION3 & TRION modules, plug them into your DEWE3 or DEWE2 instrument, turn the system on and get to work!

The module is automatically identified and configured within the software as soon as it is launched.

Choose between a wide range of TRION3 and TRION modules in the tables above:

| ANALOG MODULES | DIGITAL MODULES | POWER MODULES | ANALOG OUTPUT MODULES |

|---|