MANUFACTURING & INDUSTRIAL

If you need to reduce downtime, monitor processes, and ensure top efficiency, DEWETRON offers the perfect solution. Our customizable DAQ systems deliver reliable, gapless data recording, no matter if you want to acquire only a few or several hundred signals. The range of manufacturing & industrial testing and troubleshooting solutions (mobile and stationary) is wide so find more details below.

DEWETRON makes manufacturing & industrial testing easier with our modular measurement systems and user-exchangeable modules. We offer isolated signal inputs, gapless data recording and real-time data processing and viewing. Benefit from seamless distributed measurements, redundant storage and user-friendly design. DEWETRON’s DAQ equipment is the ideal choice for all your manufacturing and industrial applications.

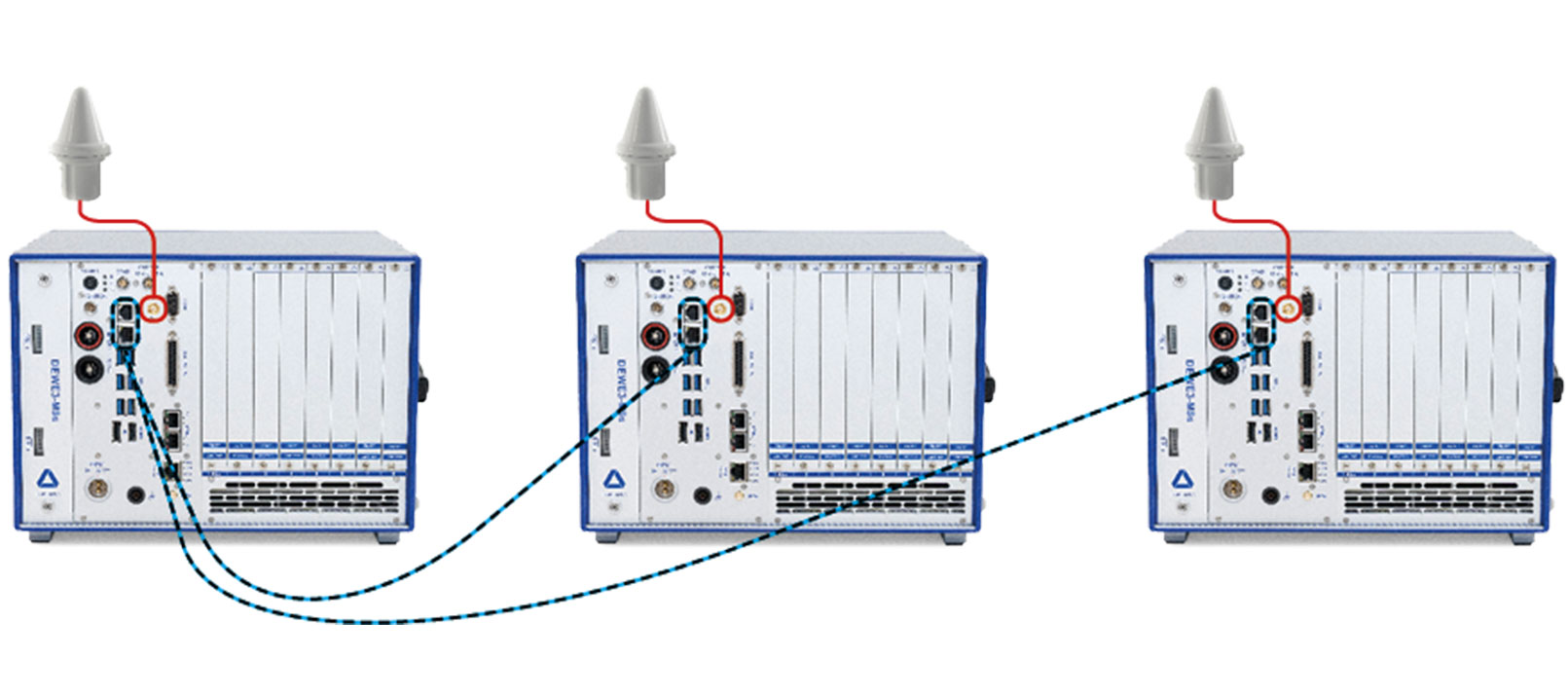

DISTRIBUTED MEASUREMENTS

Data acquisition systems for industrial measurements often require simultaneous data recording across multiple locations. This could be power transformers of an electrical grid or measurements at various points in a production plant. For these complex needs, we combine our trusted devices with cutting-edge technology to deliver synchronized, distributed measurements. Our modular DAQ systems are tailored to meet your unique requirements, ensuring seamless integration and reliable performance across all measurement points. Different possibilities for redundant data storing ensure that no data gets lost in case network troubles occur while the measurement campaign is running.

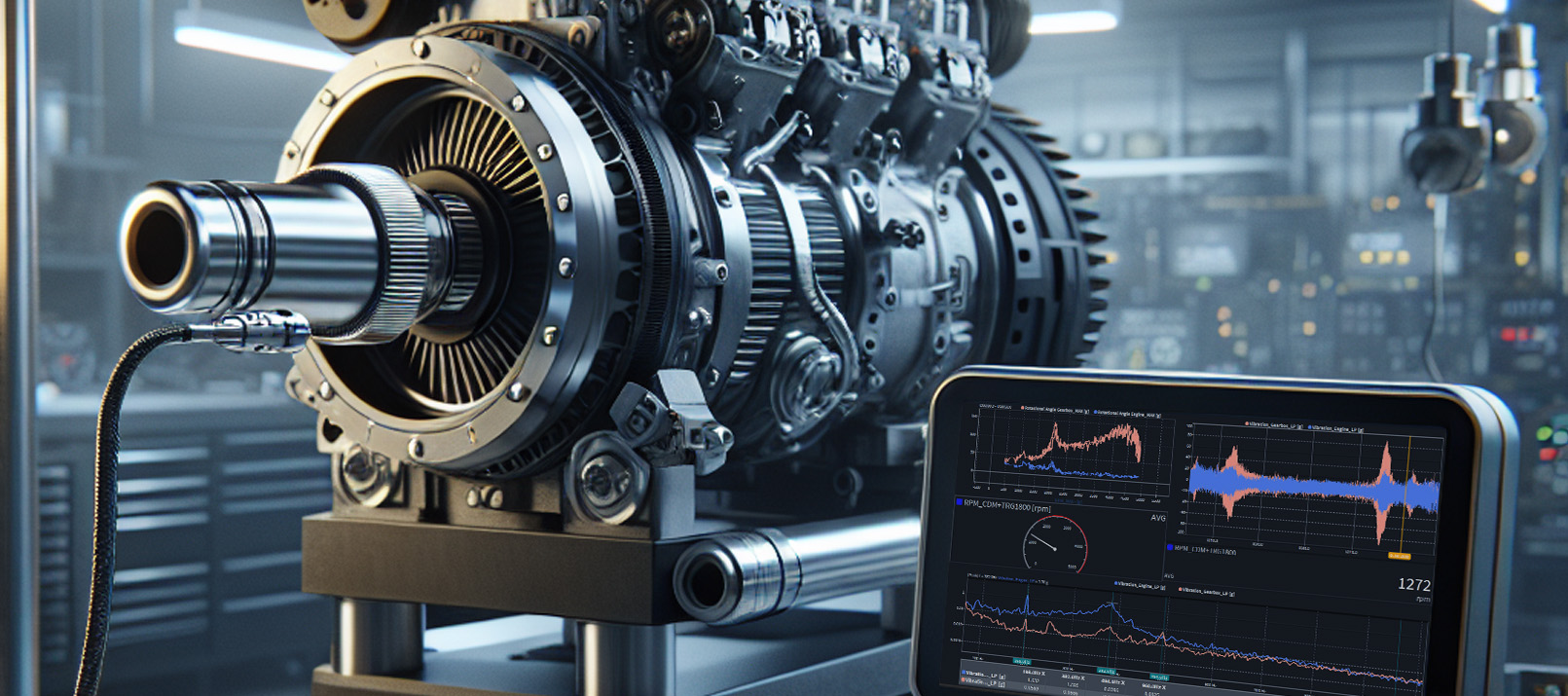

MACHINE CONDITION MONITORING & DIAGNOSTICS

Condition monitoring is essential to understand your machines’ health and performing maintenance at the right time. By monitoring critical factors like vibration, pressure or temperature during operation either continuously or in defined service intervals, you can detect faults before they lead to malfunctions. In addition, log machine protocols such as MQTT or modbus in parallel. This approach ensures that your equipment stays reliable and efficient. DEWETRON’s condition-based monitoring solutions are perfect for rotating machinery like motors and pumps. Our highly integrated hardware and software provide accurate, real-time results, making maintenance easier and more effective. Our portable solutions are the perfect choice if you need a DAQ system that must fit into the hand luggage.

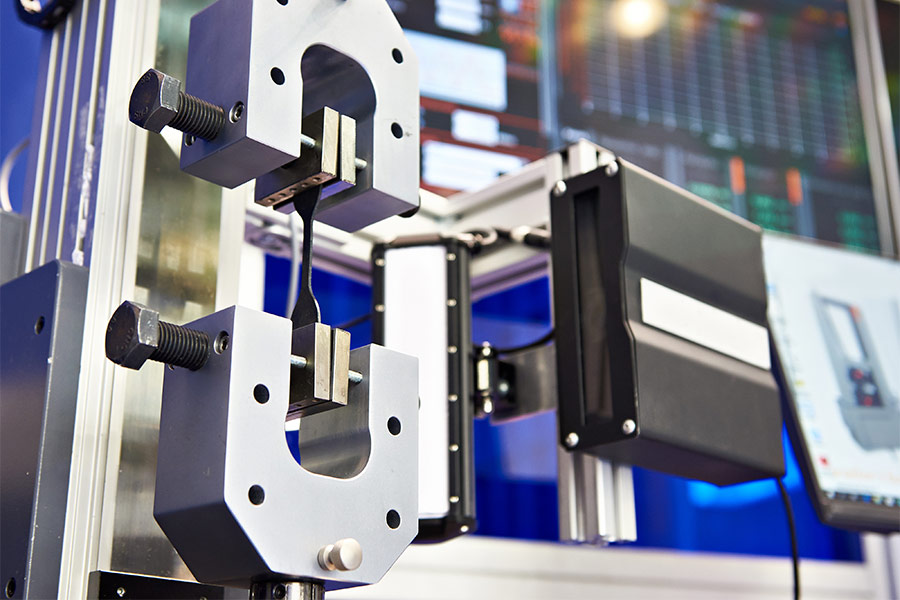

MATERIAL TESTING & FATIGUE ANALYSIS

Fatigue occurs when materials experience repeated cyclic loading, leading to progressive damage that can result in cracks and leaks. Ensuring safety in vehicle or vehicle components design, or constructing other materials is critical. DEWETRON’s fatigue analysis solutions help predict fatigue damage by measuring strain and stress. Our tools offer a range of math functions, visualization, and analysis options to provide accurate insights, helping you design safer and more reliable products.

TRANSIENT RECORDING

Short-time voltage spikes on a signal line can lead to malfunction of a system such as an ECU. Finding the root-cause for voltage spikes is essential for eliminating those. But before it must be possible to detect them. DEWETRONs highspeed signal inputs support sample rates up to 10 MS/s and provide 5 MHz analog bandwidth and will support you in finding short term spikes – even if they are shorter than 1 µs.

WELDING PROCESS ANALYSIS

To engineer and develop the welding processes you need a synchronized acquisition of voltage, current >100 A, noise, temperature, forces and many more. Besides the acquisition of physical quantities, you often also need a high-speed video >1000 fps which is captured in parallel. DEWERTON’s portfolio offers possibilities to synchronize sensor data and high-speed video data allowing you to deeply analyze and evaluate the formation of the weld, the cool down process or flying sparks.

WHITE GOODS AND HOME APPLIANCE TESTING

Also, home appliance testing can be performed with DEWETRON data acquisition equipment. Our portfolio offers you suitable measurement solutions to determine the coefficient of performance of a fridge or freezer. Determine also the power consumption and efficiency of an electric stove or evaluate the noise emission of a washing machine. Even the performance analysis of air conditioning and many more are an easy task with our DAQ systems.

FFT ANALYSIS

FFT analysis is the basic requirement for countless tests of manufacturing and industrial applications. DEWETRON’s FFT options provide you detailed insights into the frequency characteristics of your DUT.

Online and offline FFT, freely selectable number of samples, optional zero padding for enhanced line resolution and various windowing and scaling types that can be freely selected and fulfill your calculation demands. Benefit of many other features of our FFT analysis.

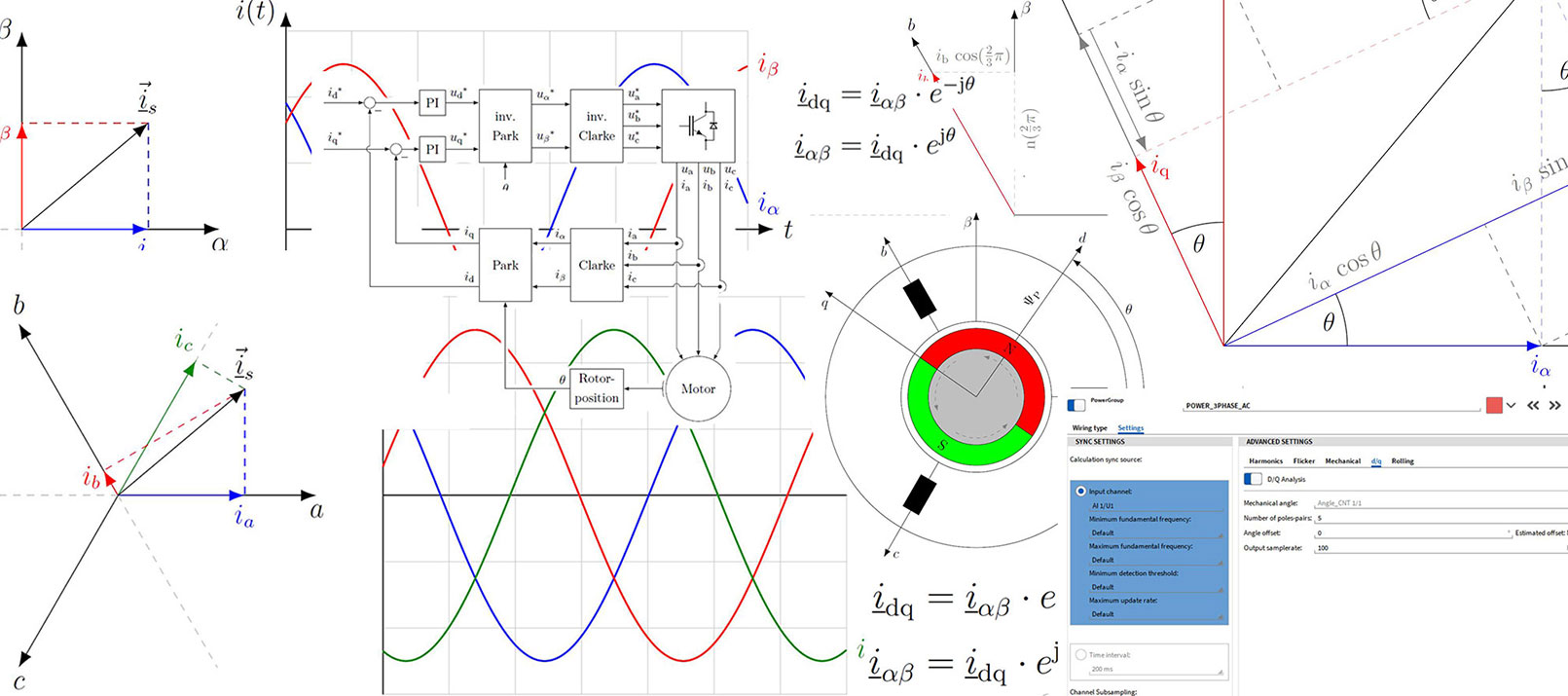

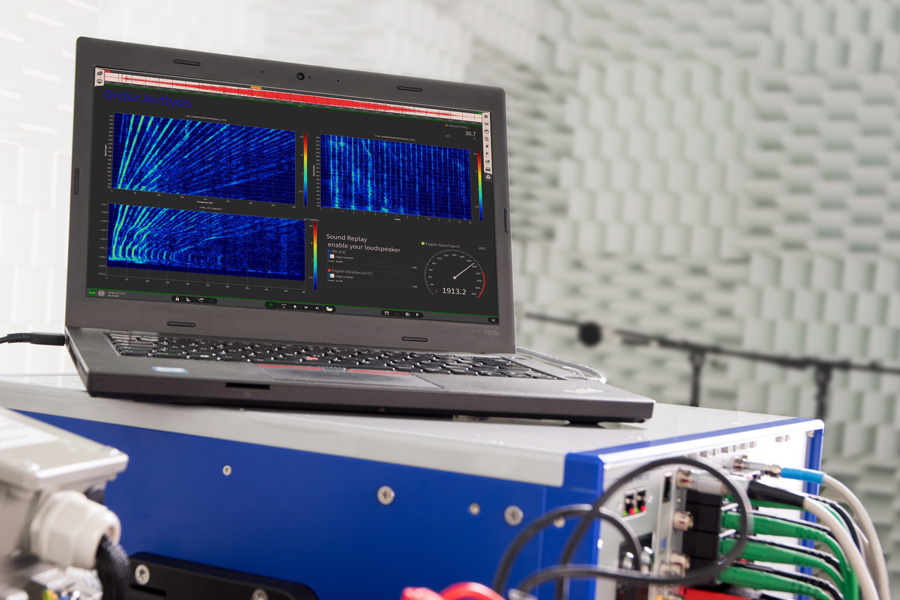

Order Analysis

Many hidden faults in rotating machines occur during start-up and coast-down. DEWETRON’s order analysis systems give deep insights into the order domain. Among others, plot of frequency vs. speed or order vs. speed are set up and created very easily and quickly. This toolbox is the perfect solution to find the reason why high vibrations in a certain frequency and speed range occur. Smart angle-based resampling algorithms ensure highly accurate and reliable measurement results. Additionally, DEWETRON’s systems offer multiple measurement capabilities, such as recorder, FFT, STFT and CPB, making them versatile for various applications.

Modal Testing

Modal testing is essential for determining natural frequencies, mode shapes, and damping ratios in structures, crucial in fields like construction and mechanical engineering. It ensures the safety and reliable performance of components of aircrafts. DEWETRON’s modal test option calculates all parameter that are needed for advanced modal analysis in 3rd party tools including the seamless data export into the common file formats. Besides that, our modal test feature is very easy to use.

NOISE EMISSION

Any DUT that has movable parts will emit structure borne and airborne sound. DEWETRON offers solutions for analyzing the sound pressure level in compliance with IEC 651 and EN61672-1. Besides overall and interval data logging freely definable percentile sound pressure levels can be determined and relevant values for labor policies such as Noise exposure level and noise dose can be calculated. CPB, FFT and STFT analysis complete the noise emission portfolio.

TORSIONAL VIBRATION ANALYSIS

Torsional Vibration Analysis is essential for understanding the noise, vibration, and harshness caused by rotating machines and engines. DEWETRON offers high-resolution measurement equipment for both torsional and rotational vibration. With capabilities like simultaneous multiple analyses, differential counter inputs with programmable trigger levels up to 40V, and digital filtering to reduce noise, DEWETRON ensures precise vibration analysis for industrial applications.