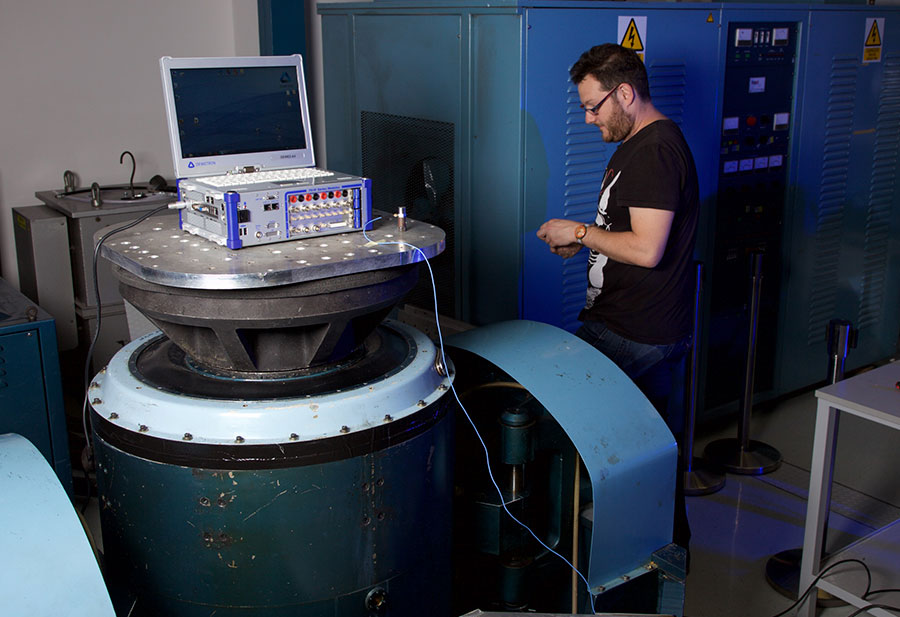

Quality & product qualification

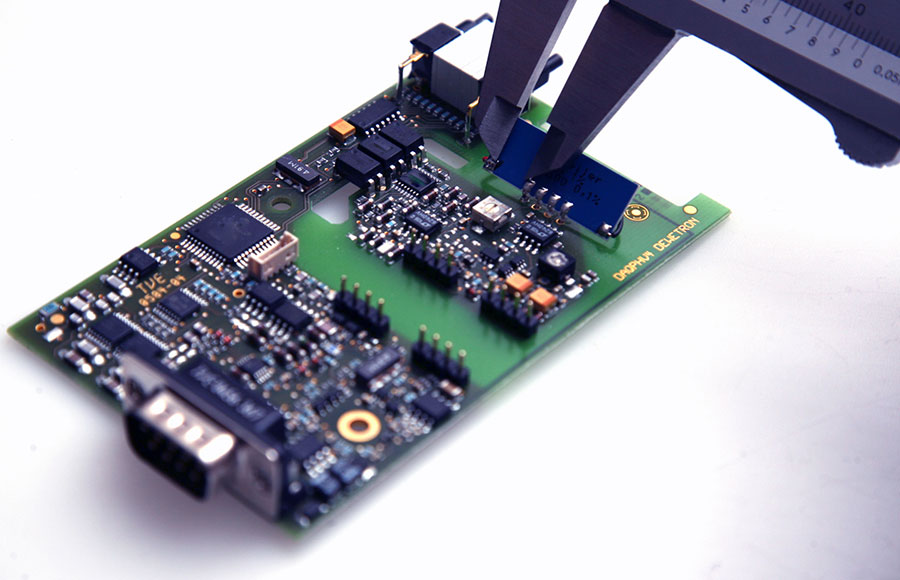

High quality is key to us. You can trust us that our entire product portfolio goes through a tough product qualification phase, before it is approved for the market.

COMMITMENT TO TOTAL QUALITY MANAGEMENT

Choosing DEWETRON means having a partner who supports you at every step. With a strong focus on quality and environmental responsibility, we earn the trust of customers worldwide through rigorous standards and reliability.

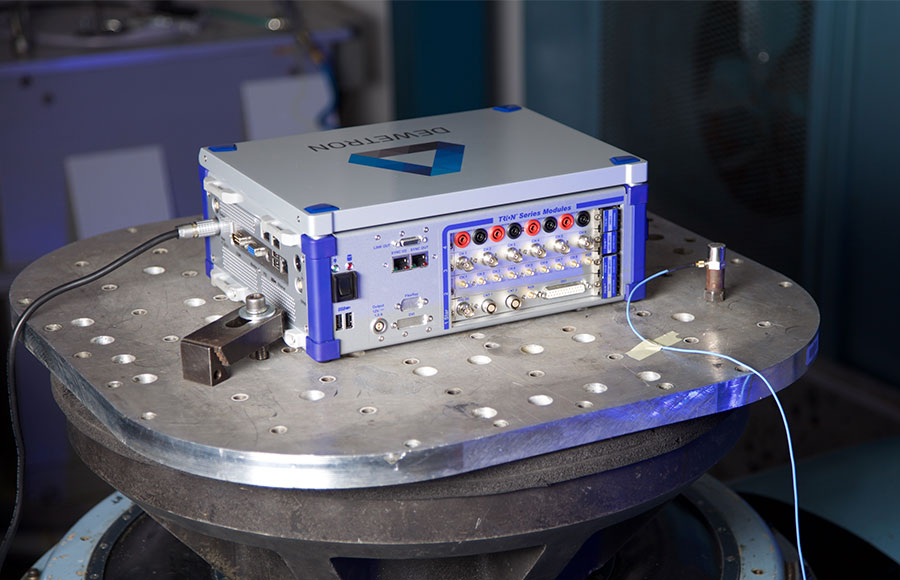

Our commitment to quality spans every step, from precise technical specifications to development, production, quality assurance, shipping, and after-sales-services like personalized support. Each component and system includes a calibration certificate for guaranteed accuracy and reliability.

These quality measures ensure our products meet your expectations and deliver long-term reliability.

CERTIFIED QUALITY

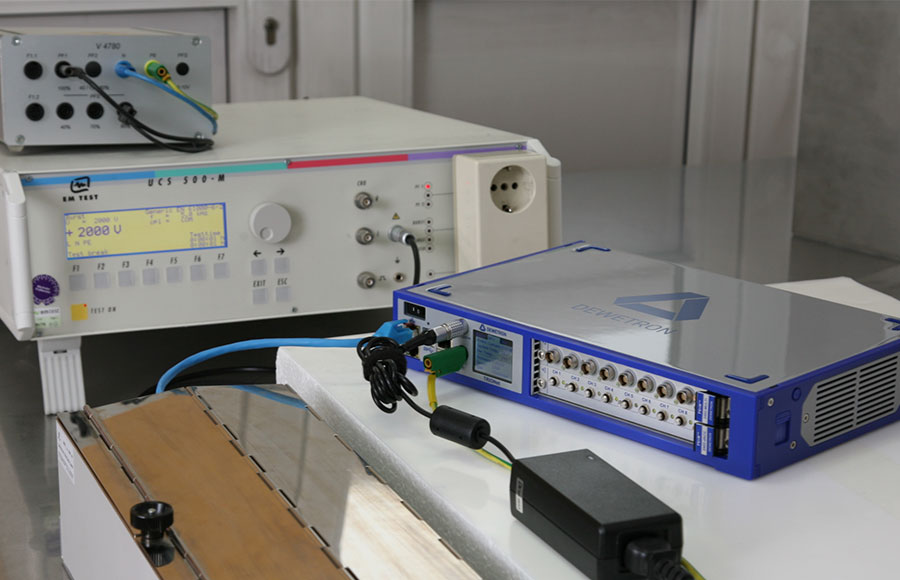

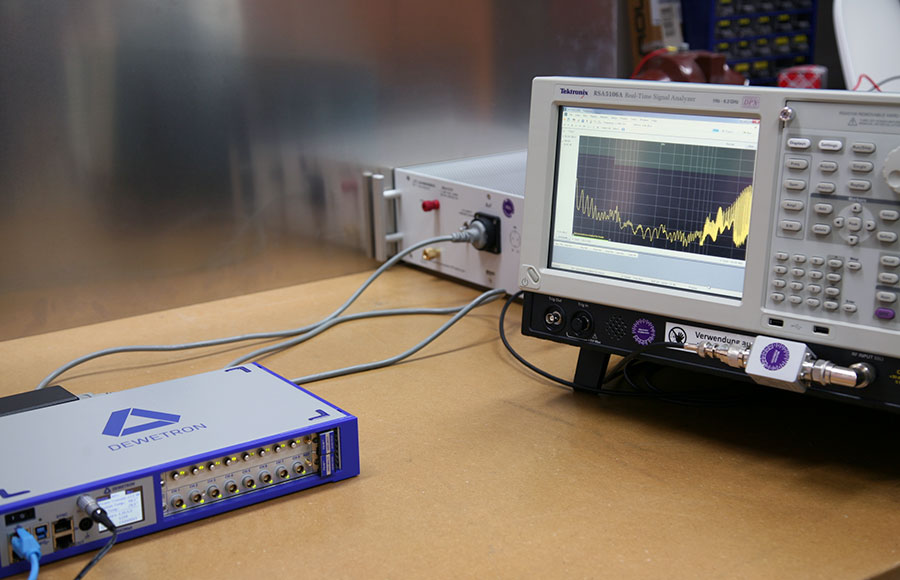

In addition to our strong commitment to total quality management, the development and production of our equipment meet the high requirements of various standards such as ISO9001, ISO14001, and ISO17025. These certifications guarantee compliance with rigorous quality procedures and documentation of every aspect of our business. Moreover, our systems meet a wide range of specifications and norms (EMI, CE, etc).

CB Scheme Testing: We test for worldwide compliance

All our products are tested by accredited labs according to harmonized standards and receive a CB scheme test report. The IECEE CB Scheme is an internationally recognized multi-lateral certification system for electrical and electronic products based on the IEC international standards. On request, we can also test against a broader range of specificationson the requirements of your unique application.