How do strain gauges work?

Strain gauges (or strain gages) are one of the most common sensor types in the industry. They can be useful in many different applications and are particularly convincing due to their relatively easy handling. You can learn more about the applications and functionality of strain gauges in this article.

What are strain gauges?

For many people, measuring their weight is part of their daily routine. But have you ever wondered how a body scale can determine your weight at all? This is possible because of force sensors, which include strain gauges.

Strain gauges usually consist of thin layers of a conductive material. If a strain gauge is stretched, its resistance and conductivity changes. Exactly this property allows the measurement of forces, which can manifest themselves in various ways.

Strain gauges are frequently used in scales. However, these are not only conventional kitchen or body scales, but also some special scales such as crane scales. It is also possible to measure other processes that lead to strain gauge deformation. First and foremost, these are material-specific properties. Here, one attaches the strain gauge to a solid using a special adhesive. If this solid expands or compresses under stress, this change in length transferres to the strain gauge which changes its conductivity. Therefore, strain gauges are often used to determine elasticity and solidity, but strain gauges can even detect oscillations and vibrations of solids.

Another application of strain gauges is in the verification of simulation computations. In engineering, the so-called finite element method is a popular simulation technique to calculate the deformation behavior of materials. One often uses strain gauges to check whether this simulation method delivers correct results.

How strain gauges work

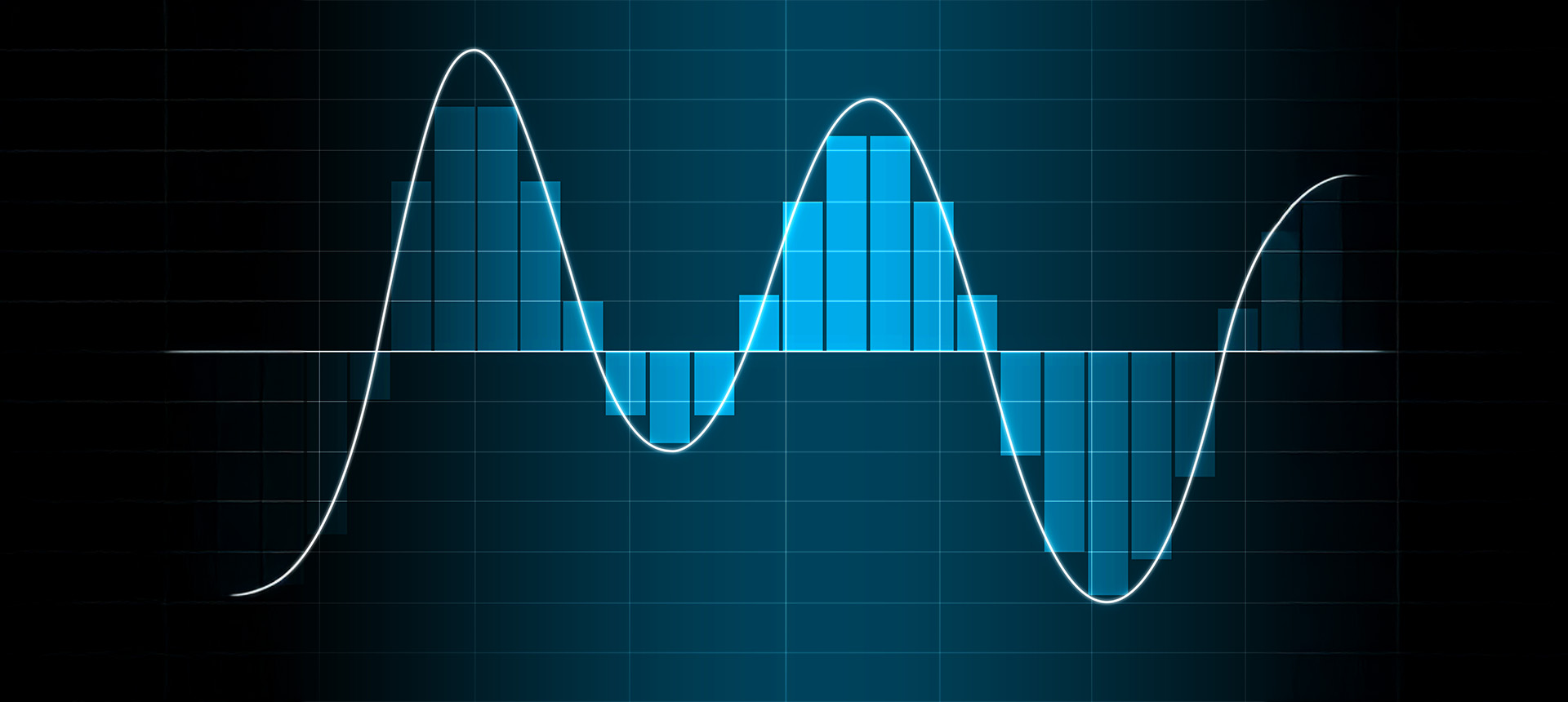

Strain gauges, as mentioned, consist of thin layers of a conductive material. The conductivity of this material often depends on the length and cross-section of the material used. A short and thick piece of cable usually has a lower resistance than a long and thin conductive cable. This is exactly why the total resistance R of a material is often expressed by its specific electrical resistance:

Here ρ is the specific electrical resistivity, l the length and A the cross-sectional area of the conductor.

When one stretches the strain gauge, the length l and the cross-sectional area A of the conductor change, and thus its total resistance R. Based on this change in resistance, it is possible to determine how much the strain gauge has expanded under stress and also what force is acting on it.

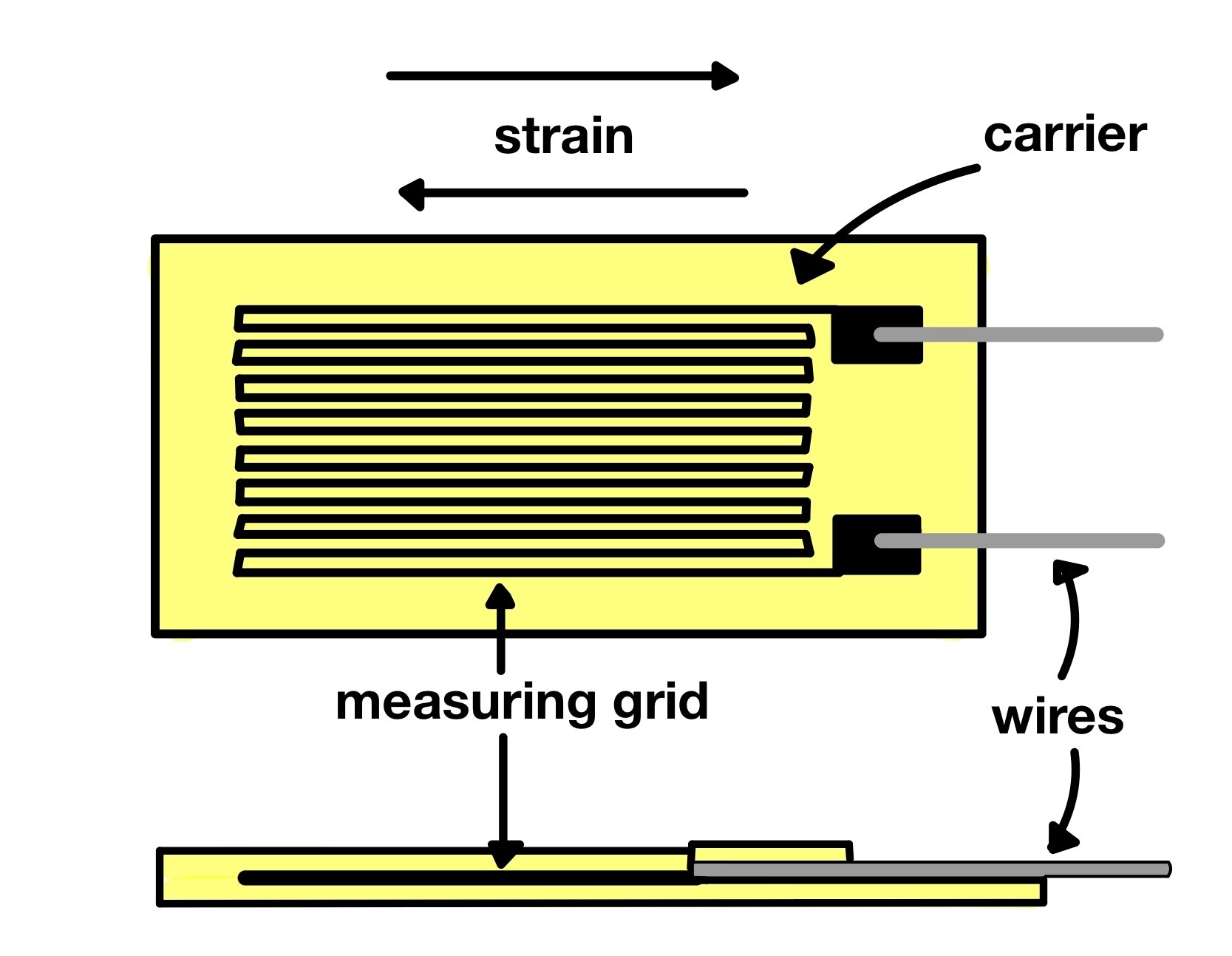

schematic construction of a strain gauge

Strain gauges can be made of various materials. Semiconductors such as silicon offer a very high sensitivity of the sensor. However, a disadvantage of such semiconductor-based strain gauges is the high temperature dependence of the material. Even a few tenths of a degree can lead to a significant change in conductivity – without any strain occurring in the material. Silicon strain gauges are therefore especially attractive for laboratory applications.

In contrast, there are also strain gauges based on metallic materials such as constant. These are less temperature sensitive, but also have lower accuracy. The relative measurement accuracy of standard strain gauges based on metallic materials is about 0.1 % to 1 %.

For very special applications, there are also other types of strain gauges. These can be based on optical, inductive or capacitive components. Among others, high-temperature strain gauges are available that provide reliable measured values of up to 1000 °C.