Calibration - What it is and why is it so important?

Calibration is an important verification process to guarantee the accuracy of a measurement system. It is important not only before the first use but also after long-term usage as systems wear out. In this blog post, we will explain what calibration is and how it works. We will describe how we calibrate systems at DEWETRON and further point out the difference between similar processes.

What is calibration?

You often may hear the term calibration in connection with the verification of test and measurement systems. Every measurement instrument is subject to certain measuring tolerances, which arise due to the respective environmental conditions or by used construction components. During calibration, the measured value displayed on the measurement instrument is compared with a reference value defined as normal. We precisely document the occurring deviations in order to find out the measuring accuracy. As part of the accredited calibration, the measurement uncertainty with which each measuring point was checked in the laboratory, is also specified. We do not change anything on the measurement device during the calibration process.

In a nutshell: Calibration is a comparison process of measurement values delivered by the device under test with those of a calibration standard (e.g. an already calibrated device) of known accuracy.

What is the difference between calibration, gauging etc.?

Adjustment, gauging, and certification are often used incorrectly as synonyms for the term “calibration”. They all have something to do with measurements and accuracy but are fundamentally different.

Gauging

Gauging is the legally prescribed testing of a measuring system for compliance with legally regulated values according to the Weights and Measures Act. Further, gauging may only be carried out by public authorities or state-certified test centers.

Excursus: A Weights and Measures Act is a kind of legislative act found in many jurisdictions establishing technical standards for weights and measures.

Adjustment

As already mentioned, calibration does NOT interfere with the measurement system. On the contrary, an adjustment is always a permanent interference in a measuring instrument by the calibration laboratory and compensates the deviation measured by the calibration.

Certification

Certification is the provision of a written assurance by an independent body that the product, service, or system in question meets specific requirements. In general, these specific requirements are either defined by a private or international technical standard.

What are the benefits?

Like any piece of equipment, a measurement system wears out over time. Contamination, dust, or simply frequent use can cause measured values to change. Sounds worrying, but it is not! Regular calibration counteracts this. It ensures the consistent quality of your measurement data and further assures that your measured values comply with the standard. In the context of quality assurance in a company, regular calibration also helps to save costs by detecting measurement deviations early enough.

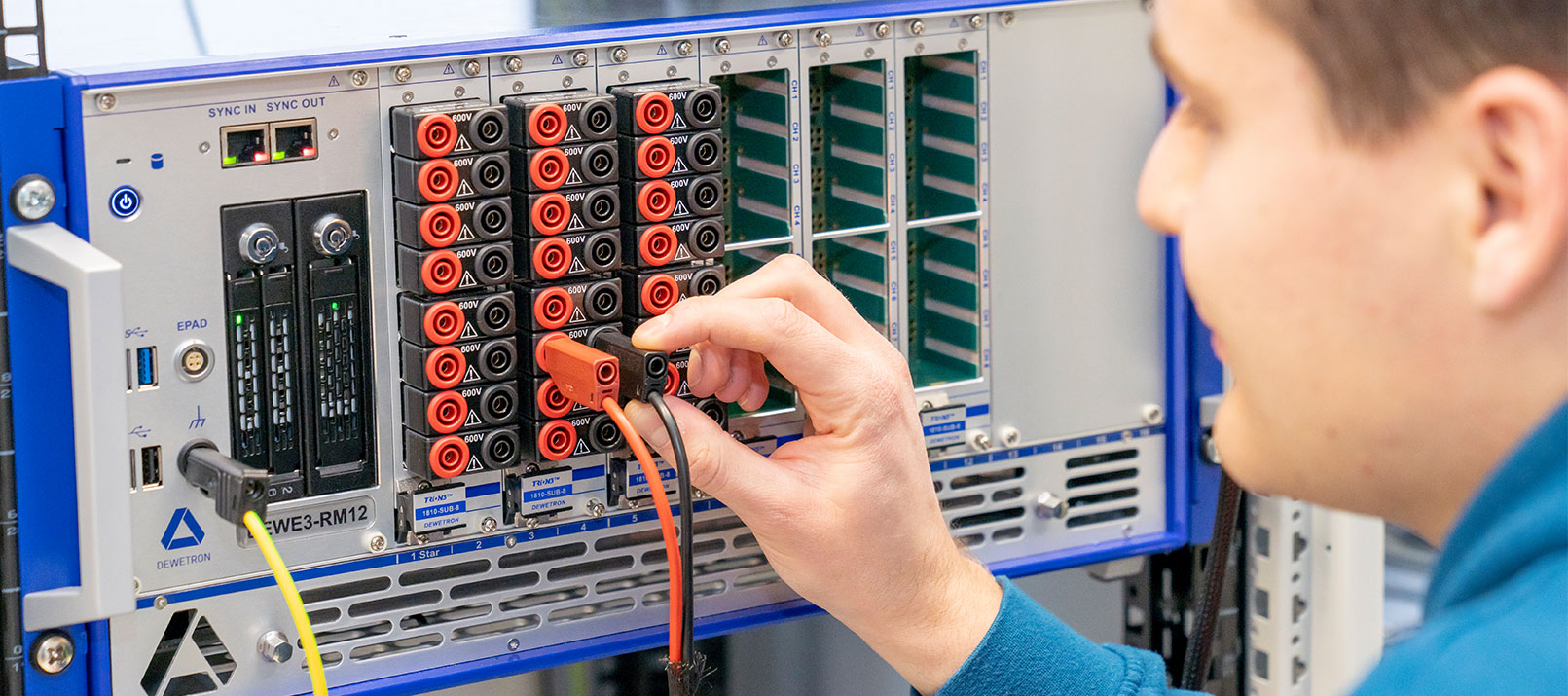

The DEWETRON calibration laboratory

The DEWETRON calibration laboratory is ISO 17025 certified, so we are authorized to issue calibration certificates according to ISO (International Organization for Standardization) standards. We are also NIST (National Institute of Standards and Technology) certified and are allowed to calibrate your instruments according to this certification. Both certifications ensure the traceability of the measurement results according to international standards.

In addition to a standard one, also an accredited calibration is possible. Accreditation means that an external authority has recognized the competence of the calibration lab. The accredited calibration also includes manufacturer adjustments and forms a significant cornerstone for the traceability and transparency of the measurement results.

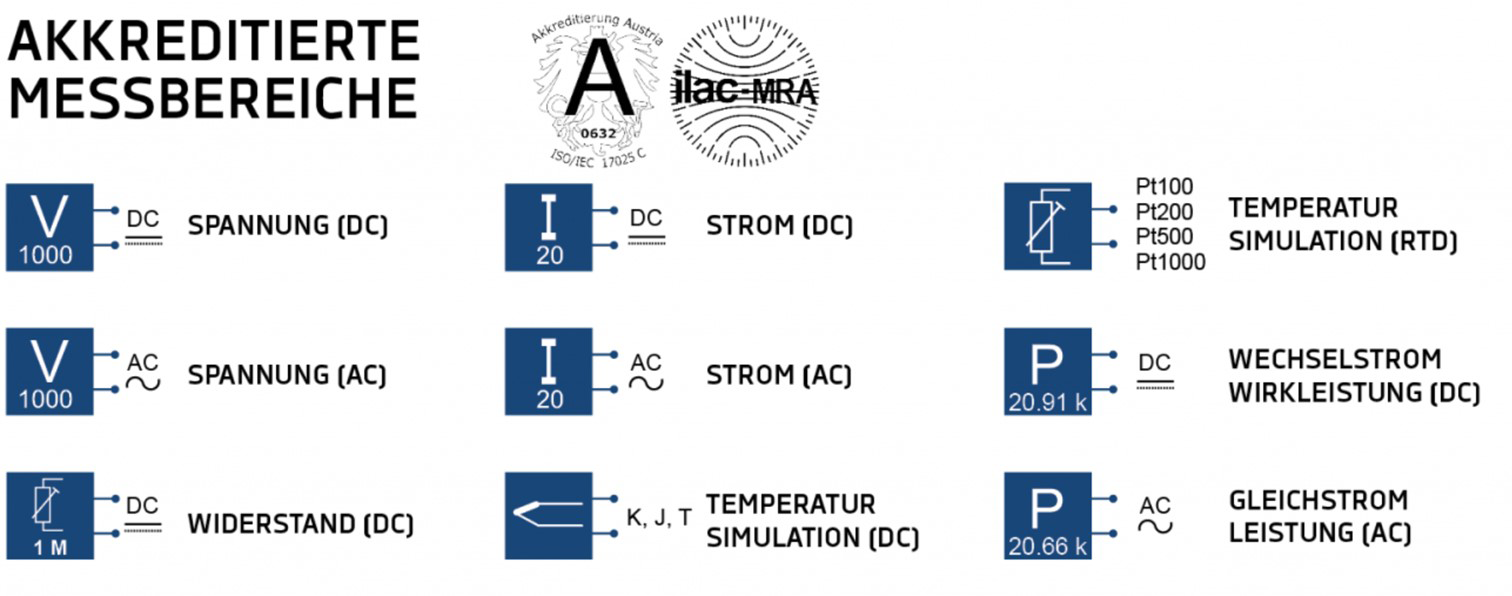

The accreditation of the DEWETRON calibration lab includes the ISO 17025 standard of Accreditation Austria plus the ILAC MRA. These authorize us to calibrate the following parameters:

DEWETRON products and services

At DEWETRON we calibrate every measurement system in our calibration laboratory before we ship it to our customers. Additionally, we perform regular calibrations of our products to ensure the required measuring quality. In general, we recommend an annual calibration of your measurement devices. With an early request we can schedule your device better and you avoid a too-long downtime of your measurement equipment. We keep your measurement system for a maximum of 14 days after it arrives, in exceptional cases also faster processing is possible as we know that a short processing time is crucial.

In addition to accredited calibration, we also offer support for your measurement systems as well as maintenance and repair. Our experienced support team will be happy to assist you with your concerns. Regular maintenance of your equipment extends its service life. If something does not work as planned, our trained technicians will put your system through its paces and perform any necessary repairs and system checks.